Name: Feed sieve shaker

Cost: Cost is unavailable for the Aviagen and Hy-Line sieve shakers (pictures shown above). The average price for similar manual feed sieves is about $250

Availability: A variety of feed sieve shakers (manual and electrical) are available on Amazon and manufacturers’ website

Intended use

A sieve shaker is used to measure the size distribution of feed particles. This tool can be used to check feed particle size in the deliveries from the feed mill and the feeding system. The uniformity of feed particle size throughout the feeding system is an important factor affecting flock performance. Feed samples from various points should be taken and tested for particle size uniformity regardless of the feed form. Feed with a high content of fine particles creates many potential issues such as compromised feed intake and nutrient absorption and air quality issues. On the other hand, particles that are too coarse increase the risk of feed separation, a situation where the birds do not receive a balanced diet by selectively eating large particles.

How does it work?

Taking feed samples for the size distribution test is a critical step. The samples should be taken from the beginning and end of the feed line and compared to each other. The sieving procedure involves passing feed through a series of sieves of progressively smaller diameters for one minute. Then the percentage of each particle size category can be calculated. As a standard method, the following classes of feed particle size are used: Particles less than 1 mm, 1 – 2 mm, 2 – 3 mm, and particles greater than 3 mm.

Standard feed particle size for broiler chickens and laying hens

The obtained results from the size distribution of feed particles at the farm level should be compared to the recommended standard values.

Table 1. Ideal particle size distribution for broiler mash feed using the Aviagen Sieve Shaker

Table 2. Target particle size distribution for broiler crumble and pellet feed using the Aviagen Sieve Shaker

Table 3. Optimal feed particle profile for laying hens using the Hy-Line Sieve Shaker

Using the device

- Remove the shaker lid by sliding it horizontally

- Slide the lid vertically into the groove in the center of the first compartment that is labeled greater than 3 mm (>3mm)

- Fill the left compartment with the feed sample

- Take the lid out of the vertical groove and slide the lid back horizontally on the shaker to close the shaker

- Turn the sieve and hold it vertically upright with the largest compartment at the top of the shaker

- Shake the sieve vigorously for about one minute

- Stop shaking the sieve after one minute and return it to the horizontal position

- Ensure the feed particles are level within each compartment before reading the measurements

- Read and record the values indicated beside each compartment (for the particles greater than 3 millimeters in the first compartment, use the values of the left-hand scale and for all other compartments, use the values on that compartment to calculate the percentages of feed in each compartment)

- Add the values of all four compartments together to get the total value

- Divide the value of each compartment by the total value to get the percentage for that section

Example calculations:

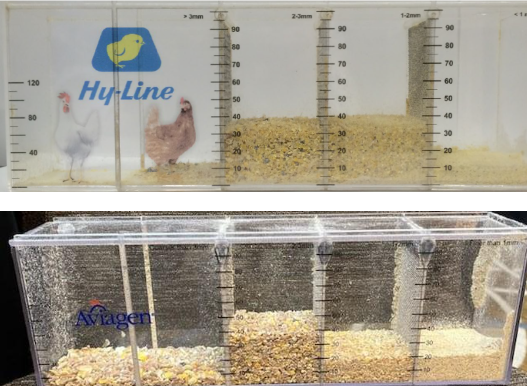

The following picture was taken by Rob Renema (Alberta Chicken Producers) at the Feed and Water Flock Talk event organized by the Poultry Innovation Partnership in Red Deer on October 19, 2022. The picture compares pellet quality (size distribution) from the beginning of the feed line (lower picture) versus the end of the feed line (upper picture). I have added the recorded numbers to each compartment of the sieve shakers in the picture to demonstrate the calculations below.

According to steps 10 and 11, add the values of all four compartments together to get the total value and then Divide the value of each compartment by the total value to get the percentage for that section

- Calculations for the sieve shaker at the bottom:

- Total value = 100 + 40 + 10 + 5 = 155

- Calculate the percentage of feed in each compartment from the left side:

- First compartment (coarser than 3 mm): (100 ÷ 155) × 100 = 64.5%

- Second compartment (2 – 3 mm): (40 ÷ 155) × 100 = 26%

- Third compartment (1 – 2 mm): (10 ÷ 155) × 100 = 6.5%

- Fourth compartment (finer than 1 mm): (5 ÷ 155) × 100 = 3%

- Calculations for the upper sieve shaker:

- Total value = 50 + 35 + 10 + 5 = 100

- Calculate the percentage of feed in each compartment from the left side:

- First compartment (coarser than 3 mm): (50 ÷ 100) × 100 = 50%

- Second compartment (2 – 3 mm): (35 ÷ 100) × 100 = 35%

- Third compartment (1 – 2 mm): (10 ÷ 100) × 100 = 10%

- Fourth compartment (finer than 1 mm): (5 ÷ 100) × 100 = 5%

The above calculations show that the pellet feed from the end of the feed line contains more fine particles and less coarse than 3 mm particles compared to the feed sample from the beginning of the feed line. In an ideal situation, the changes in particle size distribution at different points of the feed distribution system should be minimal.

About the author(s)

-

Mohammad Afrouziyehhttps://poultryinnovationpartnership.ca/person/mohammad-afrouziyeh/

-

Mohammad Afrouziyehhttps://poultryinnovationpartnership.ca/person/mohammad-afrouziyeh/

-

Mohammad Afrouziyehhttps://poultryinnovationpartnership.ca/person/mohammad-afrouziyeh/

-

Mohammad Afrouziyehhttps://poultryinnovationpartnership.ca/person/mohammad-afrouziyeh/